丽水棱工阀门

丽水棱工阀门

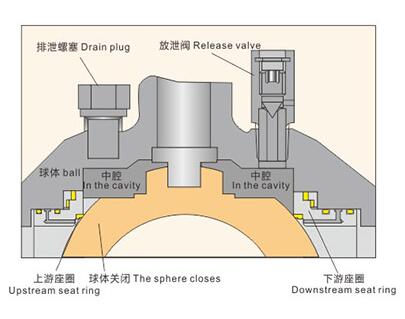

固定式球阀都带有浮动阀座,受介质压力后,阀座产生移动,使密封圈紧压在球体上, 以保证密封。通常在与球体的上、下轴上装有轴承,操作扭距小,适用于高压和大口径的阀门。

Fixed ball valve with floating seat medium pressure, seat movement, seal pressed in on the ball,to ensure the sealed. Usually in the sphere of the upper and lower shaft with bearings, smalloperation twist, suitable for high pressure and large diameter valves.

.jpg)

.jpg)

.jpg)

.jpg)

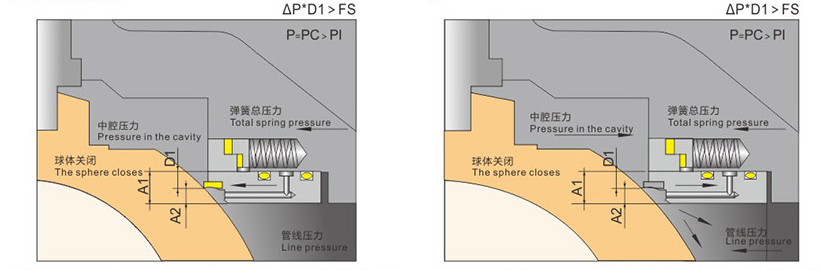

当阀门中腔压力(PC)小于座圈弹簧的预紧力(FS)和管线流体压力

反之,当阀门中腔压力(PC)大于座圈弹簧的预紧力(FS)和管线流体压

(P1),即OP*D1> FS,则球体和阀座预紧力接触确保密封。

力(P1),即OP*D1> FS时,中腔压力将座圈轻微推开,使之与球体之间产生一小间隙,这样内腔过载压力自动泄放到管线中,重新达到阀门中腔和管线(_上下游)的压力平衡。

If the pressure of cavity(PC) less than set ring spring pre-tightened

Vice versa, If the pressure of cavity(PC) larger than set ring spring

stres(FS) and fluid pressure(P1): OP*D10 FS, good sealing can be

pre-tightened stress(FS) and fluid pressure(P1): OP*D1>FS,The

realized when ball contacts with seat.

body cavity pressure pushes slightly the seat ring away, and therewill be a ltte gap between seat ring and ball, in this way, theoverloading pressure will be bled off into the pipeline and achievepressure balance again.

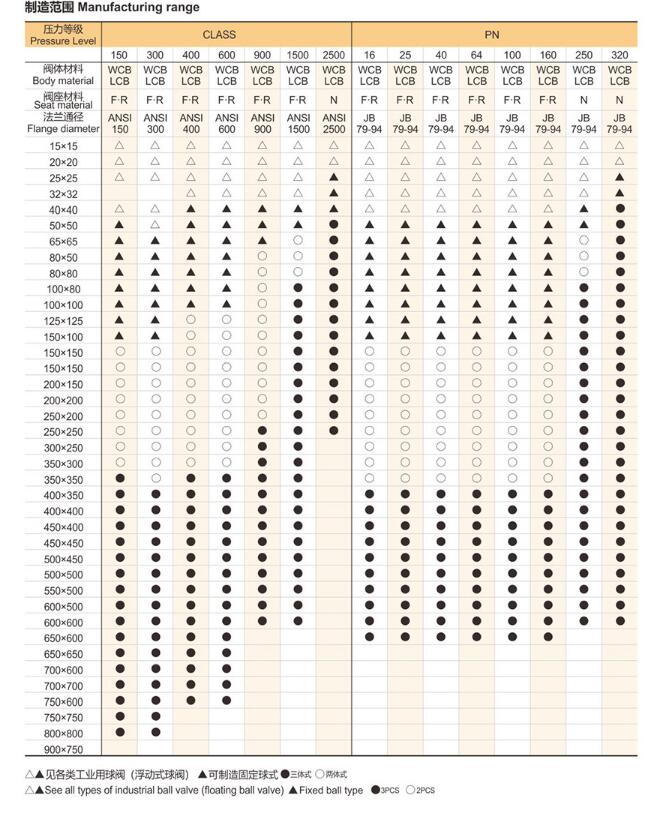

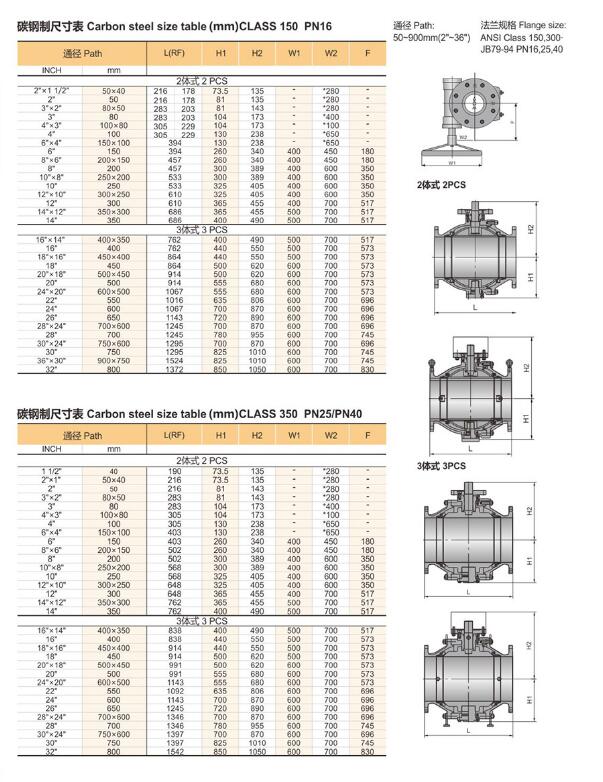

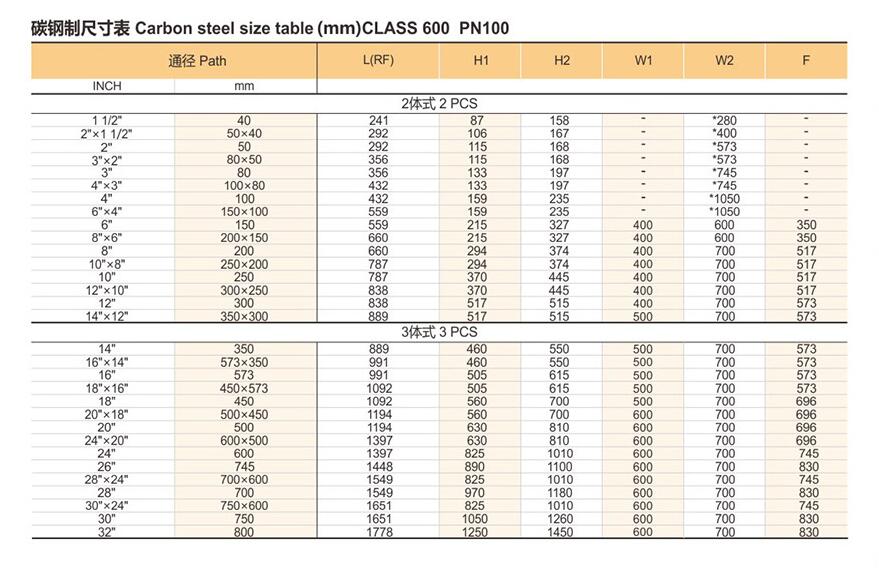

CLASS150, 300·PN16, 25,40 通径 Path 150-900mm(6"~38")

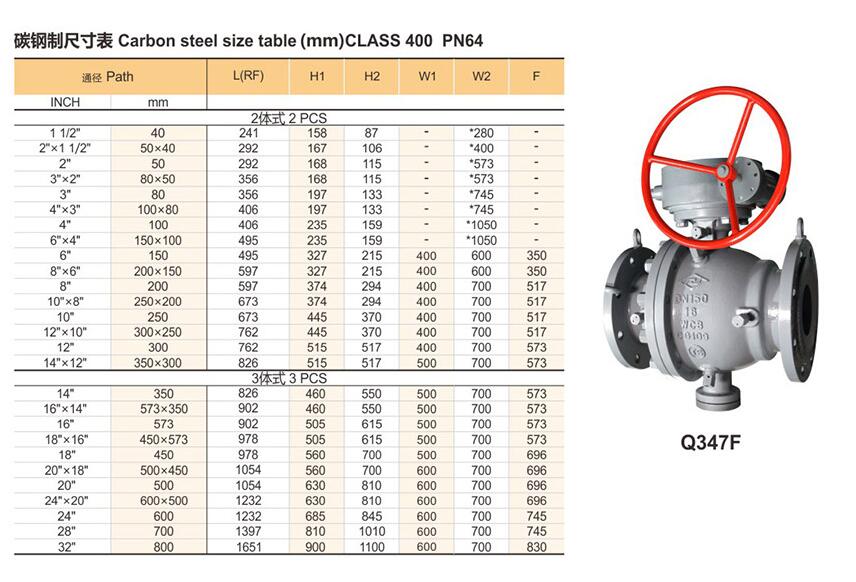

CLASS400, 600·PN64, 100 通径 Path 50-750mm(2"~30")

CLASS900, 1500·PN160,250 通径 Path 400-600mm(1-1/2"~24")

使用温度: -29C~100C;-46C~150"C

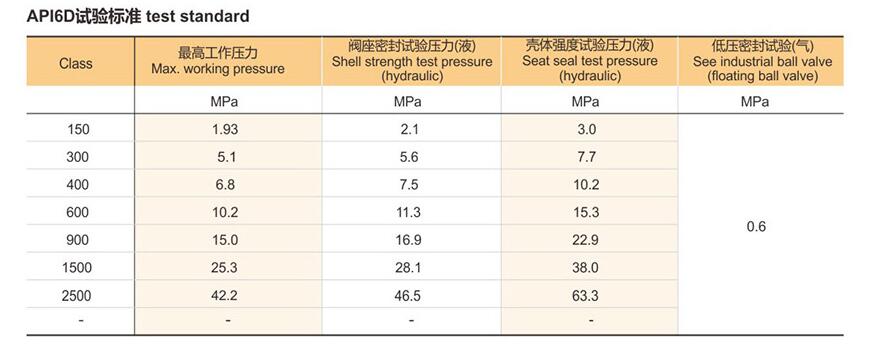

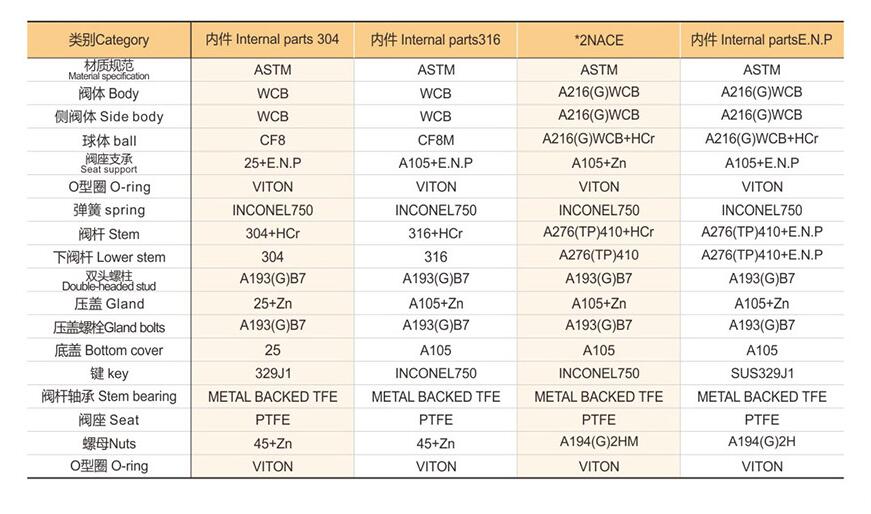

压力等级:下列最高工作压力为碳钢阀体常温时的极限工作压力,

Pressure rating-- -The below working pressure refers to the maximum

各种阀体材质工作压力与温度对应,详见温度压力线表。

working pressure for carbon steel body. More details of all body material'sworking pressure and temperature, check the temperature and pressuretable.

it: F:iS3TFE R:XtR N:/EJ

Note:F: Reinforced TFE, R: Synthetic rubber, N: Nylon

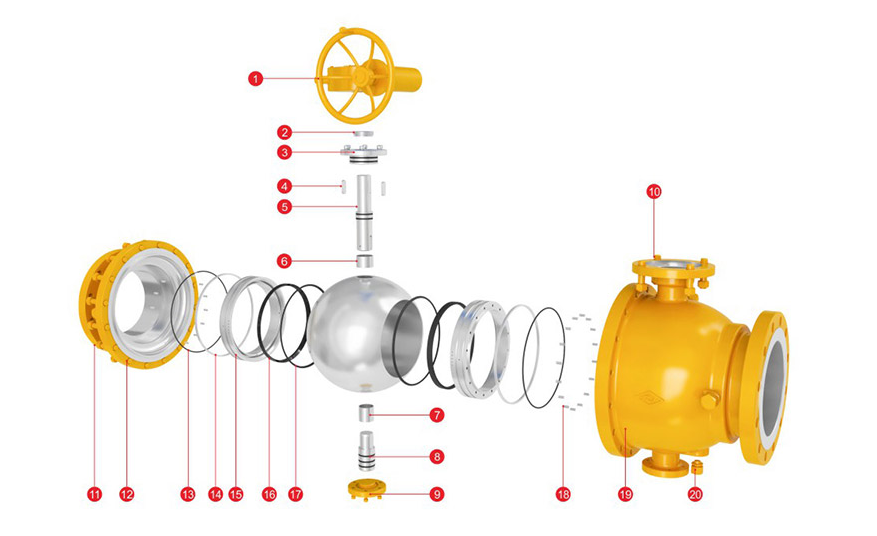

Basic design

T8Eâ -API6D;ANSIB16. 10;GB12221-05

Face to face dimension according to API6D;ANSIB16. 10;GB12221-05Flange ends standard according to ASMEB16.5;MSS SP44;JB79-94

itÈt0t8 -ASMEB16.5;MSS- SP44;JB79-94

Welding ends according to ASMEB31.8;ANSIB16.25

#8 -ASMEB31.8;ANSIB16.25

Working temperature 29%C- 100"C;-46'C~150"C